Protect Your Warranty

Did you know that 90% of outboard warranty claims are denied due to salt corrosion?. Manufacturers view corrosion as "lack of maintenance," leaving you to foot the bill for expensive repairs. Corrosion is neglect.

The New Standard in Flushing

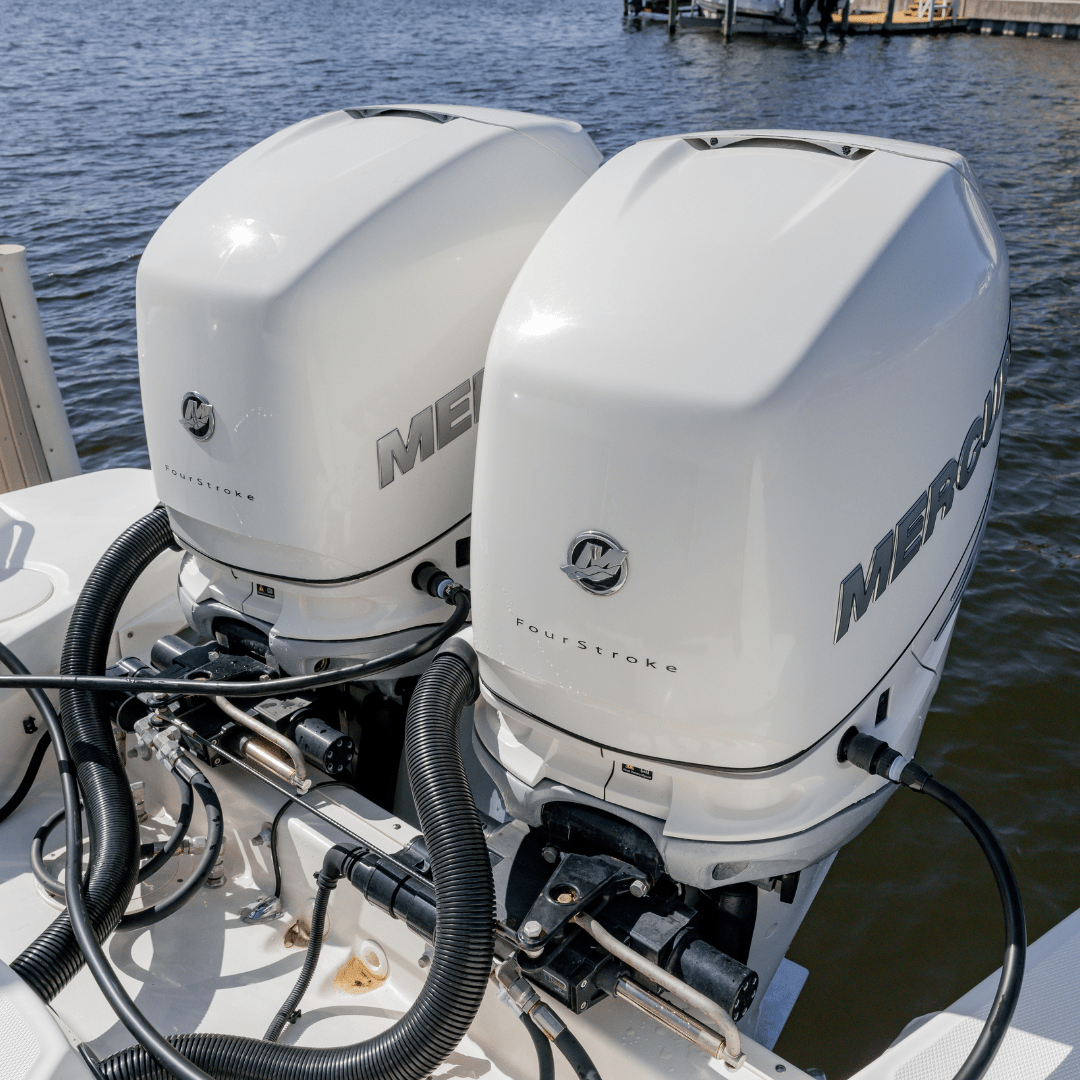

Many boaters still rely on "muffs" and idling engines, but modern outboard design has evolved. Most engines built in the last 15 years feature dedicated, built-in flush ports. These ports allow you to flush the entire cooling system—including the critical top of the block—with the engine completely off.

When you connect to the flush port, water is directed through the engine’s internal galleries via pressure, not the water pump. This eliminates the noise, heat, and safety risks of running a motor on the trailer or lift, while ensuring fresh water reaches the thermostat housing and cylinder heads where salt likes to hide.

Why Traditional Methods Fall Short

Muffs are Risky

Running on muffs is noisy and dangerous. If the muff slips, you risk overheating your block in seconds.

The Fix: Flush with the engine off—exactly how the manufacturers intended.

Velocity is Key

Splitting one hose into multiple engines (Y-Valves) kills water pressure. If you don't have velocity, you aren't moving salt.

The Fix: Sequential flushing ensures 100% water pressure to every engine, every time.

Stop Adding Idle Hours

Muffs require the engine to be running. Why add unnecessary idle hours to your motors just to perform basic maintenance?

The Fix: Flush while the engine is cold and off. No noise, no heat, no unnecessary wear.

No dRained Batteries

Built-in systems are hardwired to your boat’s 12V battery. Forget the switch once, and you’re stuck with a dead battery at the ramp.

The Fix: Our system is self-powered. Zero drain on your boat's electronics and no complex wiring.

Following the Owner's Manual

Knowing you have a flush port is only half the battle; using it correctly is what saves your engine. Manufacturers like Mercury, Yamaha, Honda, and Suzuki specify that for a flush to be effective, it must be a 15-minute freshwater rinse.

This 15-minute duration isn't arbitrary—it’s the time required for fresh water to fully displace salt brine and begin breaking down mineral scale in the tightest cooling passages. Doing this one engine at a time ensures 100% water pressure is maintained, which is vital for "lifting" salt out of the block.

For an even deeper clean, many captains use a salt-dissolving solution like Star brite® Salt Off® during the rinse cycle to help break down stubborn mineral deposits. These solutions are compatible with Flushmaster.

What Happens if YOu Don't

The Heat Factor: Salt buildup acts as an insulator. Even a thin layer of scale inside your engine's cooling passages makes your motor run hotter, reducing efficiency and longevity.

The Crystal Effect: When salt water sits in a hot engine, the water evaporates and leaves behind jagged salt crystals. These crystals can eventually block water flow entirely, leading to catastrophic engine failure.

The Protection: A thorough, freshwater flush "lifts" these deposits before they have a chance to bond to the metal internal components.